Both the EU’s legal framework and consumer needs demand the use of recycled plastics in food packaging. For example, the draft of the Packaging & Packaging Waste Regulation (PPWR) calls for a mandatory recycled content in contact-sensitive packaging (such as food contact). The CORNET projects SafeCycle and PolyCycle have already carried out important preliminary work in this area: Plastic recyclates were tested with regard to their suitability for use in food packaging. Of particular relevance here is the presence of DNA-reactive, mutagenic substances, which must be classified as particularly critical in terms of health and for which very low limit values apply. In order to evaluate their presence, chemical analysis (GC-MS and HPLC-MS) was combined with in vitro bioassays (miniaturized Ames test) in the projects. It was found that polyolefin and polystyrene (PS) recyclates in particular lead to questionable results if they were primarily produced from packaging with certain colour components (printing inks, e.g. nitrocellulose-based, colour pigments or labels). In the bioassays, specific indications of the presence of DNA-reactive, mutagenic substances were found, which still have to be identified using chemical methods.

For the use of polyolefin and PS recyclates in food contact, these substances must be removed or excluded. Since decorative elements (e.g. printing inks) have a complex chemical composition and various types of colouring elements are used, the ColourCycle project aims to further investigate which coloured components in packaging can lead to the formation of DNA-reactive, mutagenic substances during recycling and how these could be removed, e.g. by deinking. For this, defined coloured and deinked samples are to be analyzed using chemical analysis and in vitro bioassays in order to draw conclusions about the materials and deinking processes. In order to be able to process a small quantity of defined samples on a laboratory scale in a representative manner, a methodology is to be developed to simulate the effects of recycling processes on the material in a realistic manner. Furthermore, a challenge test for printing inks will be set up to determine the efficiency of deinking processes and thus include the removal of critical substances. These findings can ultimately be incorporated into the evaluation of recyclates in order to identify safe recycling materials and processes for food contact.

Project Goals:

- Method development for the simulation of mechanical recycling processes and the production of coloured recyclates on a laboratory scale

- Systematic analysis of various coloured recyclates using chemical analysis (GC/MS and HPLC/MS) and biological tests (miniaturized Ames test)

- Development of a model challenge test for deinking processes and determination of cleaning efficiencies

- Identification of measures to enable the use of coloured or mixed recycling streams in food contact

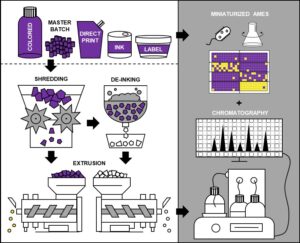

Figure 1: Schematic overview of the project: Preparation of defined coloured samples through

simulation of a mechanical recycling process and their analysis with in vitro bioassays and chemical methods.

The ColourCycle research project is being carried out as part of the 38th CORNET call for proposals (Collective Research Network) in cooperation between the research partners Fraunhofer Institute for Process Engineering and Packaging IVV, Austrian Research Institute for Chemistry and Technology (OFI), and University Campus Vienna (HCW). In Germany, it is managed as a project of the Industry Association for Food Technology and Packaging (IVLV) and financed by the German Aerospace Center (DLR). The project is coordinated in Austria by the plastics cluster of ecoplus. Niederösterreichs Wirtschaftsagentur GmbH and is financed by the Austrian Research Promotion Agency (FFG).